Environmental responsibility and safety

2021 highlights

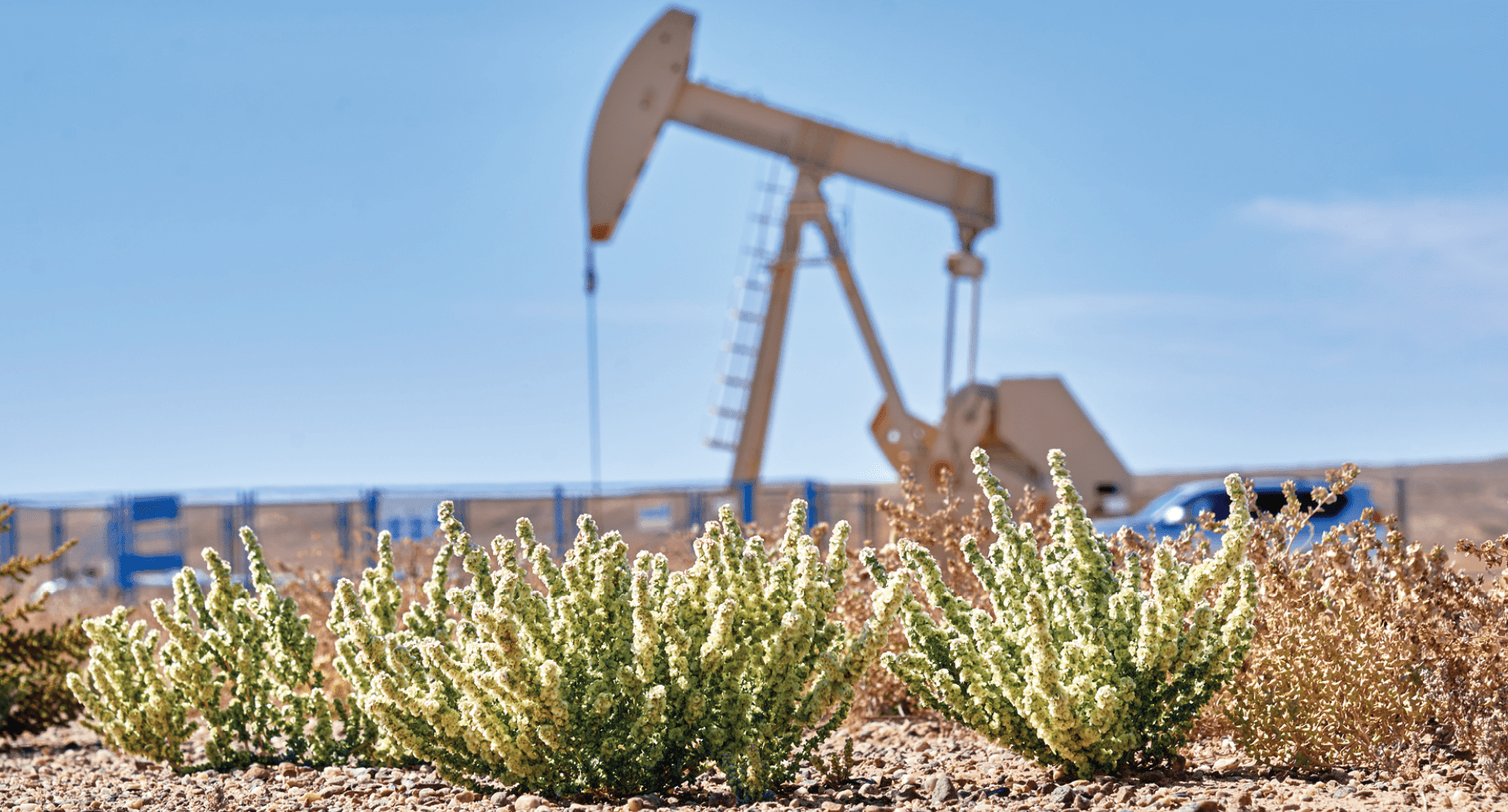

KMG Group's goals in HSE management are directly related to its Development Strategy. KMG’s Development Strategy until 2031 (the Strategy) covers strategic initiatives to promote greater environmental responsibility. KMG Group’s environmental priorities include management of greenhouse gas emissions, water resources and production waste, flaring reduction, and land reclamation.

Management teams at JSC NC KazMunayGas and its subsidiaries and associates take a zero tolerance approach to losses and harm caused by environmental pollution. In accordance with the new Environmental Code, KMG’s Environmental Policy was updated in 2021 to ensure the collection, accumulation, storage, analysis, and dissemination of environmental information. In addition, KazMunayGas enhanced its commitment to the sustainable use of natural resources and compliance with biodiversity conservation measures.

In an effort to minimise raw gas flaring, in 2015 the Company supported the World Bank’s initiative Zero Routine Flaring by 2030. In reducing our GHG footprint, we focus on increasing associated petroleum gas utilisation and recovery while minimising flaring. Raw gas flaring reports under the Initiative are submitted on an annual basis to the World Bank’s representative office in Kazakhstan.

As a result of its efforts to improve environmental performance and ensure openness and transparency in that area, KMG has topped, for the fifth consecutive year, the Environmental Transparency Rating of Oil and Gas Companies in Kazakhstan compiled by independent experts from the World Wildlife Fund (WWF), Creon Group, and AKRA rating agency.

| Year | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| SOx emissions intensity | 0.32 | 0.25 | 0.20 | 0.23 | 0.22 |

| NOx emissions intensity | 0.25 | 0.20 | 0.21 | 0.22 | 0.24 |

| Raw gas flaring rate | 11 | 6 | 2.95 | 2.2 | 2.1 |

| Raw gas utilisation, % | 85 | 93 | 97 | 98 | 98 |

The Company remains committed to being an environmentally responsible business, further enhancing its environmental protection management system, maintaining dialogue with all stakeholders on this matter, and thus delivering on its commitments as stated in the Company’s Environmental Policy.

KMG is aware of the importance of its environmental impact and strives to minimise it.

As part of the Year of the Environment, a number of activities were implemented to ensure environmental safety, such as working to dispose of historical oil waste and decontaminate oil-contaminated soils. Efforts were stepped up to promote environmental protection issues among employees, participation in tree planting events, development of action plans to reduce atmospheric emissions, implementation of environmental protection programmes, and other activities.

The World Cleanup Day 2021 was held on 17 September 2021 in 180 countries across the world. As part of that global movement and the republican eco-initiative “Birge-taza Kazakhstan!” (Together – Clean Kazakhstan!), as well as the Year of the Environment, KMG organised a Tree Planting Event jointly with the Almaty District Akimat of Nur-Sultan. The Company’s employees planted about 100 pine trees in the capital during the city-wide clean-up day on 18 September.

The commitment to environmental responsibility is also reflected in the tree planting carried out by KMG’s subsidiaries and associates. As part of the efforts to carry out the commission of Kassym-Jomart Tokayev, the President of Kazakhstan, concerning the planting of over 2 billion trees in the forest area and 15 million trees in settlements, as announced in the Address to the People of Kazakhstan, and to fulfil the Comphrehensive Action Plan, provisions are also made for KMG’s subsidiaries and associates located in the Atyrau Region to carry out activities in 2021–2024 as part of the Tree Planting by Major Oil Companies programme. All of KMG’s subsidiaries and associates are working to plant trees and shrubs in sanitary protection zones and in the regions of their footprint. For example, employees of JSC Karazhanbasmunai cleaned up and planted 3,000 seedlings at the Karazhanbas field and at a number of socially significant facilities in the Mangystau Region. Pavlodar Refineries planted 6,680 trees in a sanitary protection zone on an area of 21.5 hectares. The company’s employees planted 84 trees on the industrial site.

In April 2021, the Akimat of the Atyrau Region and JSC Embamunaigas signed a Memorandum on Tree Planting in the Atyrau Region with a total area of 243.2 hectares. As part of the tree planting programme, arrangements were made to implement the initiative “Soil Survey on the Allocated Land Plot”. Based on the results of the soil survey efforts and identification of suitable areas for planting, it is planned to carry out tree planting work in the area.

Atyrau Refinery LLP received land plots in Atyrau, with a total area of 1,420.9 hectares, including 860.9 hectares in the Tukhlaya Balka evaporation field, under the Memorandum on Tree Planting in the Atyrau Region signed in April 2021 with the Akimat of the Atyrau Region.

To fulfil the terms of the Memorandum, a research company with expertise in forest cultivation was engaged to work on an area of 560 hectares. Based on the results of the survey, no greenery will be planted on the allotted plot, with efforts being taken to identify a new one. Once an additional land plot is identified for planting, the factory will develop a land improvement and planting project, determine the estimated cost and the scope of work, and put together a schedule of work.

Atyrau Refinery LLP carried out additional land improvement and tree planting work on a 5 hectares land plot located in a sanitary protection zone (SPZ) to the west of the refinery (which is not included in the approved draft substantiation document for the SPZ in terms of tree planting).

Priority environmental projects

Project: TAZALYQ

The TAZALYQ project provides for the upgrading of Atyrau Refinery’s wastewater treatment facilities as well as the reclamation of the Tukhlaya Balka evaporation fields.

Project: Construction of a formation water treatment plant at the Karazhanbas field

The construction of a formation water treatment plant at the Karazhanbas field will solve the water shortage problem at the field.

Project: Automated environmental monitoring information system

It is used at the stage of generation and submission of numerous environmental reports, as well as planning of environmental protection efforts.

The objective is to obtain accurate and reliable data and generate complete and up-to-date environmental information required for implementing an effective environmental policy and putting together development programmes.

Recovery of historical oil wastes and oil-contaminated soil treatment

Complete disposal of historical oil waste and oil-contaminated soil treatment through 2024.

Employee training in environmental management

People are our most important asset, so HSE training remains top of mind for KMG Group. Therefore, mandatory staff education, training and upskilling in occupational health, industrial and fire safety and environmental protection are priority training areas for KMG.

Since 2021, mandatory training sessions for KMG CC employees in occupational health and industrial and fire safety basics have been held on the platform of KMG Engineering LLP.

In 2021, KMG Group spent a total of KZT 498,714,000 to train 61,678 employees, including HSE training in the following key business segments: KZT 215,745,000 in the upstream business; KZT 78,409,000 in the midstream business; KZT 98,495,000 in the downstream business; KZT 106,065,000 in the service business; and KZT 0 in the KMG Corporate Centre.

The training in occupational health, safety, and environmental protection issues is carried out in accordance with the “70/20/10” / “on-the-job / internal / external” training model using our own existing training facilities / centres. Mentoring and internal coaching programmes are implemented for long-service employees, with master classes and trainings conducted as well as various contests to recognise best performers, which enhances internal communications and motivates personnel to strive to excel in their jobs.

The companies that have their own training facilities / centres include JSC Ozenmunaigas (Zhanaozen), JSC KazTransOil (Aktau), Pavlodar Refinery LLP (Pavlodar), and Oil Services Company LLP (Aktau).

| Indicator | 2019 | 2020 | 2021 |

|---|---|---|---|

| Employees trained | 116,890 | 89,715 | 61,678 |

| Amount in KZT ’000 | 1,056,067 | 578,891 | 498,714 |

| Business segment | Number of employees | Amount in KZT ’000 |

|---|---|---|

| Upstream | 31,068 | 215,745 |

| Midstream | 2,024 | 78,409 |

| Downstream | 12,046 | 98,495 |

| Service | 16,496 | 106,065 |

| KMG Corporate Centre | 44 | - |

Energy saving and energy efficiency programmes

KMG has continued its group-wide energy saving and energy efficiency programme, with the KMG Corporate Centre collecting and analysing energy consumption and energy efficiency-related data, monitoring the dynamics, identifying opportunities for improvement, and conducting year-on-year and peer benchmarking (IOGP).

KMG’s energy saving and energy efficiency efforts are based on the methodology set out in ISO 50001 Energy management systems, an internationally recognised best-practice framework for systemic energy management.

Energy saving and energy efficiency programme performance

In 2021, total energy consumption amounted to 166.4 mln GJ, up 6% year-on-year, including 13.1 mln GJ in electricity, 4.3 mln GJ in heat, 1.4 mln GJ in motor fuel, and 147.7 mln GJ in boiler and heating fuel (with natural gas accounting for 45% of the total energy consumption). The total energy consumption is divided among three business segments: Upstream, Midstream, and Downstream.

The year-on-year energy consumption increase was mainly due to higher gas transportation in 2021 driven by the stabilisation of the pandemic situation.

In 2021, KMG Group’s self-generated energy amounted to 547.1 mln kWh in electricity and 4,108 ths Gcal in heat.

The use of innovative technologies and renewable energy sources is a relatively new yet promising trend in the oil and gas industry.

Energy intensity

In 2021, KMG Group’s energy consumption in the upstream sector averaged at 2.4 GJ per tonne of hydrocarbon production, still 58% above the International Association of Oil & Gas Producers (IOGP) average for 2020, i.e. 1.4 GJ per tonne of hydrocarbon production. In oil production, specific energy consumption increase was primarily due to a higher water cut at mature fields, which caused a higher density of the fluid produced and, accordingly, a higher energy consumption for artificial lift.

KMG Group’s key strategic energy saving and energy efficiency initiatives include process equipment upgrades, deployment of energy saving technologies, optimisation of heat generation and consumption, and the development of the Group’s own generation assets, including APG-fired generation.

In 2021, 49 energy saving and energy efficiency initiatives were implemented. The target annual fuel and energy savings amounted to 0.34 mln GJ, which in physical terms corresponds to 5.3 mln kWh of electricity and 8,107,000 m³ of natural gas.

Given the country’s ambitions and expectations, KMG plans to acquire a stake in the existing alternative energy assets (wind and solar power plant projects) or build new renewable energy power plants of at least 300 MW in capacity, which will be approximately 945 mln kWh of “green” energy production by 2031.

We benefited from a range of renewable energy sources deployed by JSC NC QazaqGaz, with the total renewable energy generation in 2021 broken down by source as follows:

- Geothermal energy (heat) generation by heat pumps totalled 678.54 Gcal in 2021. Waterkotte geothermal heat pumps for heating and hot water supply (HWS) are operated by JSC Intergas Central Asia.

- Electricity generation by solar panels for KTG Group totalled 109,068 kWh.

- Electricity generation by solar panels for the lighting of the territory of the Engineering and Technical Centre of JSC ICA totalled 7,776 kWh.

- Electricity generation by the solar panels installed on the pig launchers for the gas pipeline branches at the Terenuzyak and Zhosaly automated gas distribution stations of the Kyzylorda UMG (Main Gas Pipeline Administration) amounted to 5,092 kWh.

- Electricity generation by the solar panels installed at the block valve stations for the linear portion of the Kazakhstan – China gas pipeline was 96,200 kWh.

- In 2021, PKOP solar panels and autonomous street lamps (combined solar and wind generators) generated 47,000 kWh and 3,000 kWh of electricity for street lighting in the area respectively.

Climate change and greenhouse gas emissions

Management

KMG’s long-term Development Strategy prioritises the following climate-related initiatives:

- greenhouse gas emissions management

- reduction of routine flaring

- improvement of GHG emissions intensity per unit of production and overall energy efficiency

- reduction of methane leaks

- increased financing for green projects.

The global trend to fight climate change is increasingly affecting companies across the world. In furtherance of the government policy on the low-carbon development of the country, KMG has approved its 2022–2031 Development Strategy, which meets high safety standards and the sustainable development principles. According to KMG’s Development Strategy, low-carbon development to reduce the carbon footprint is one of the Company’s key priorities.

Because the climate agenda is strategically important, the Company has developed a Low-Carbon Development Programme for 2022–2031 (the “LCDP” or the “Programme”) which defines KMG’s climate ambitions, key approaches, and measures to reduce the carbon footprint. In striving for low-carbon production, KMG pursues a balanced approach, targeting a 15% reduction in direct and indirect CO2 emissions by 2031 from the 2019 level of 1.6 mln tonnes of CO2.

In addition to the Programme’s main focus on improving the energy efficiency of the operating processes and implementing renewable energy projects, the Company is also planning to implement additional decarbonisation measures, specifically: carbon capture, utilisation and storage (CCUS) projects, development of hydrogen energy, and implementation of forest-climate projects.

Risks and opportunities

The corporate risk management system is a key component of the corporate governance system, and is used to identify, evaluate, monitor and mitigate potential risks that may hinder the achievement of strategic goals. The Company implements a range of initiatives to minimise such risks, with risk reports submitted to the Board of Directors on a quarterly basis.

Information disclosure

As part of the CDP, KMG discloses direct and indirect greenhouse gas emissions data, greenhouse gas management issues, and key risks and opportunities for all KMG assets, including international assets in Romania and Georgia, starting from 2019.

In July 2021, the KMG Climate Change 2020 Questionnaire was published. According to the report, the direct carbon dioxide emissions at KMG Group’s level totalled 8.7 mln tonnes in 2020 (9.7 mln tonnes in 2019). The CO2 equivalent data are presented using the global warming potential set out in the IPCC Fifth Assessment report (28 for methane and 256 for nitrous oxide).

The greenhouse gas emissions data were verified by an independent accredited organisation’s report for each subsidiary or associate. Data for 2021 will be disclosed in KMG’s CDP report to be published in Q3 2022. We seek to ensure consistency and comparability when preparing our disclosures. We are committed to enhancing disclosures and increasing the scope of reporting around our Scope 3 emissions.

For more details on air protection, see the Sustainability Report.

Efficient use of raw gas

The management of greenhouse gas emissions and the reduction of gas flaring are among the priority tasks for KMG Group. According to the approved Environmental Policy, the Company strives to achieve zero routine gas flaring and reduce atmospheric emissions from flares. In reducing our GHG footprint, we focus on increasing raw gas utilisation and recovery while minimising flaring. The measures taken so far within our raw gas processing and development programmes have increased internal gas use for heat and electricity generation.

In 2021, raw gas utilisation rate was 98%, with flaring at 2.1 tonnes per 1,000 tonnes of produced hydrocarbons (2.2 tonnes in 2020 and 2.95 tonnes in 2019), down 5% year-on-year and 74% lower than the IOGP industry average.

In 2015, KMG supported the World Bank’s Zero Routine Flaring by 2030 initiative. KMG strives to minimise raw gas flaring. Raw gas flaring reports under the Initiative are submitted on an annual basis to the World Bank’s representative office in Kazakhstan.

For more details, see KMG’s Sustainability Report.

| Indicator | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Total raw gas flaring, mln m3 | 315.8 | 148.9 | 80.2 | 57.6 | 52.5 |

| Raw gas utilisation,% | 85 | 93 | 97 | 98 | 98 |

| Raw gas flaring rate, tonnes per 1,000 tonnes of produced hydrocarbons | 11 | 6 | 2.95 | 2.2 | 2.1 |

Waste management

KMG’s production operations generate production and consumption waste. KMG Group develops and implements a set of measures to improve the waste management system, keeps records of waste generated and accumulated, including contractors’ waste, and performs the safe accumulation of waste until it is recovered or disposed of. In 2021, KMG’s expenses for the recovery of waste generated and accumulated totalled KZT 12.9 bln.

It is important to emphasise that in selecting waste recovery methods, priority is given to modern waste recovery technologies, including those that cause no secondary pollution of the environment.

On 6 August 2019, a Memorandum of Cooperation was signed by and between the Ministry of Ecology, Geology, and Natural Resources of the Republic of Kazakhstan and KMG with historical oily waste disposal and oil contaminated soil remediation commitments until 2024, inclusively. The memorandum covers Mangistaumunaigaz, OzenMunaiGas, and Karazhanbasmunai.

Starting September 2019, inventories of contract lands were conducted to determine waste characteristics, the content of oil products in the waste, and the waste volume. On the basis of the inventories made, the relevant remediation projects for oil-contaminated soil were developed and agreed upon with the government authorities, with safe and efficient technologies for oily waste disposal selected and recommended and schedules drawn up for oil-contaminated soil remediation through the year 2024, inclusively.

In addition, although Embamunaigas and Kazakhturkmunay are not covered by the commitments under the Memorandum, they work to eliminate historical pollution too.

All of the above companies have entered into long-term contracts with organisations specialising in the disposal of historical oily waste and clean-up of oil-contaminated soil.

In 2021, a total of 540,475 tonnes of historical waste was disposed of at KMG subsidiaries’ and associates’ facilities, with their disposal sites remediated.

KazTransOil completely reclaimed historically polluted lands in sections 984–985 km of the Uzen-Atyrau-Samara oil pipeline.

The total area of reclamation of historically oil-contaminated lands for the KMG group of companies is 48 hectares.

For more details, see KMG’s Sustainability Report.

Asset retirement obligations

Oil and gas assets

Under the terms of certain contracts, in accordance with legislation and regulatory legal acts, KMG has legal obligations to dismantle and liquidate fixed assets and restore land plots at each of the fields. In particular, KMG's obligations include the gradual closure of all non-productive wells and actions to permanently terminate operations, such as dismantling pipelines, buildings and reclamation of the contract area, as well as decommissioning and preventing environmental pollution obligations at the production site.

The Company calculates asset retirement obligations separately for each contract. The amount of the liability is the present value of the estimated costs that are expected to be required to settle the liability, adjusted for the expected inflation rate and discounted using average long-term risk-free interest rates on government debt of transition economies, adjusted for risks inherent in the Kazakhstan market.

As of 31 December 2021, the carrying amount of the Company’s provision for liabilities to liquidate oil and gas assets was KZT 67 bln (31 December 2020: KZT 66 bln) (details in the consolidated financial statements).

Trunk oil and gas pipelines

In accordance with the Law of the Republic of Kazakhstan “On Trunk Pipeline”, which entered into force on 4 July 2012, two subsidiaries of KMG, JSC KazTransOil and JSC Intergas Central Asia, which is a subsidiary of JSC KazTransGas, have a legal obligation to liquidate the main pipeline after the end of operation and the subsequent implementation of measures to restore the environment, including land reclamation. The provision for the obligation to abandon pipelines and land reclamation is estimated based on the cost of dismantling and reclamation works calculated by KMG. As of 31 December 2021, the carrying amount of KMG Group’s reserve for the obligation to abandon pipelines and land reclamation of the Company amounted to KZT 35 bln (as of 31 December 2020: KZT 114 bln) (details in the consolidated financial statements).

Environmental remediation

KMG also makes estimates and makes judgements on the formation of reserves for obligations for environmental clean-up and rehabilitation. Environmental costs are capitalised as an expense based on or attributable to their future economic benefits.

The Company’s environmental remediation reserve represents management’s best estimates based on an independent assessment of the expected costs required for KMG Group to comply with the existing Kazakh and European regulatory frameworks. As of 31 December 2021, the carrying amount of the provision for environmental liabilities was KZT 63 bln (31 December 2020: KZT 65 bln) (details in the consolidated financial statements).

Water protection

Water is an integral part of all KMG production processes. In its activities, the Company strives to reduce water consumption, increase water use efficiency, drive up water reuse and recycling, improve the quality of effluents, and minimise the impact on natural water bodies.

KMG is a vertically integrated company engaged in the production, transportation, and processing of hydrocarbons. All processes require significant use of water. KMG takes water from surface and underground sources, municipal water supply systems, and the Caspian Sea. Wastewater from KMG’s operations mainly received by specialised receivers: storage ponds, evaporation and filtration fields. Those facilities are technical structures designed for natural treatment of wastewater and preventing environmental pollution. Operations that do not have their own storage facilities transfer wastewater to dedicated companies for treatment and disposal. The quality standards for discharged water established by environmental laws are met through the use of mechanical and biological methods of effluent treatment. However no wastewater is discharged into surface natural water bodies.

Atyrau Refinery

The Tazalyq project is one of the main ongoing environmental initiatives of Atyrau Refinery LLP. It includes an upgrade of mechanical and biological treatment facilities, the construction of an advanced treatment facility, and the upgrade of the evaporation fields.

Most of the facilities have been built as part of the first stage of the mechanical treatment plants upgrade. The new mechanical treatment facilities will reduce water intake from the Ural River by 10%, and 15% of the factory’s treated plant effluents will be reused. Presently, construction and installation works are underway for oil sludge pre-treatment and dewatering units. At the second stage, balancing and flotation units will be built.

In addition, work is underway on the reclamation of 860 hectares of Tukhlaya Balka evaporation fields. To date, the construction of a dyke between the city part and the factory part of the fields and dykes dividing the fields into four sectors has been completed in full.

In June 2021, Atyrau Refinery and the European Bank for Reconstruction and Development entered into an agreement on financing the TAZALYQ project to the amount of up to $ 80 mln. The implementation of the TAZALYQ project will enable the refinery to introduce modern “green” technologies for wastewater treatment.

Construction of desalination plants near the Kenderly recreational zone, Mangystau Region

KMG is implementing a project to build a 50,000 m3 per day seawater desalination factory with a trunk pipeline nexty to the Kenderly recreational zone. The purpose of the project is to provide drinking water to the population of the city of Zhanaozen to meet the existing water shortage and reduce the load on the Astrakhan – Mangyshlak main water pipeline. At the moment, the project is planned to be implemented in 2021–2024.

JSC Karazhanbasmunai

Presently, the Karazhanbas field takes water from the Astrakhan – Mangyshlak water pipeline. That source is insufficient to replenish the company’s water needs due to the introduction of new production facilities. To address the issue, it was proposed in September 2019 that a desalination plant be built for produced water.

For now, the construction and installation works at the factory are 72% complete. The treatment capacity for produced water will be 42,500 m3, with desalinated water output at 17,000 m3 and treated water at 25,500 m3 per day. At the factory, water will go through five stages of purification, and the output water will be close to drinking water. Thus, 17,000 m3 of water per day, which the field takes from the Astrakhan–Mangyshlak water pipeline, will be “released” for the population.

The erection of the building itself was completed as was the construction of steel tanks that were successfully hydrotested.

For more details on KMG’s water management and related projects, see KMG’s Sustainability Report.

KMG Group’s water footprint and water management disclosures were posted on the CDP’s website as part of the 2020 Water Security Questionnaire. Data for 2021 will be disclosed in Q3 2022.

For more details, see KMG’s published reports, which are publicly available at: